Service Lunch Recap: Data Spaces in Manufacturing – From Connected Production to Shared Value

November 24, 2025, by Jürg Meierhofer, Expert Group Smart Services and Clemens Neuwirth, Concircle

On November 21, 2025, the Expert Group Smart Services gathered for an inspiring Service Lunch to explore one of the most pressing topics in modern manufacturing: Data Spaces and their role in creating shared value across connected production networks.

Why Data Spaces Matter

Manufacturing companies are often sitting on a rich set of data, but leveraging it beyond corporate silos remains a challenge. Issues like interoperability, trust, and governance often hinder collaboration. This is where Gaia-X and Data Spaces come into play: they provide a European framework for data sovereignty, interoperability, and secure exchange, enabling organizations to collaborate without losing control of their data.

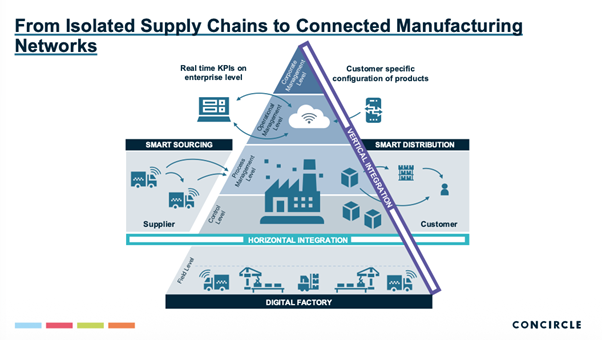

From Isolated Supply Chains to Connected Networks

The vision presented by Clemens Neuwirth (Concircle) was clear: integrated, efficient processes powered by smart sourcing, smart distribution, and horizontal integration. Real-time KPIs, customer-specific configurations, and digital factories are no longer futuristic concepts are becoming reality through Data Spaces.

Key Highlights

- Challenges in the Data Economy: Data is valuable but often trapped in silos. Making it discoverable and usable requires shared rules and partner verification.

- Gaia-X Framework: Establishes principles and governance for trusted data sharing.

- Industry Initiatives:

- Catena-X (Automotive): Operationalizes Gaia-X for the automotive value chain.

- EuProGigant (Manufacturing): A lighthouse project showcasing federated data sharing and compute-to-data concepts.

- Ideal Component Matching: A practical example from the bilateral Austrian-German research project EuProGigant demonstrates how intelligent use and sharing of measurement data can reduce costs, save time, and improve quality in spindle assembly.

The Future of Manufacturing

By connecting MES, ERP, and Data Spaces, manufacturers can move from isolated supply chains to connected manufacturing networks, unlocking new efficiencies and collaborative opportunities. Data remains at its source, queried on demand, ensuring security and sovereignty while enabling advanced use cases like compute-to-data and edge computing.